Restaurant inventory management remains a blind spot for many businesses, with restaurants wasting up to 10% of the food they purchase before it reaches customers. Food costs account for 28-35% of a restaurant’s total expenses, and this waste has a significant impact on the bottom line.

Most restaurant owners still stick to outdated inventory methods like FIFO (First-In, First-Out) without questioning how well it works. FIFO comes highly recommended for perishable goods, but experience shows it doesn’t hold up well in busy kitchens. The numbers tell the story – 26% of restaurant operators name food and inventory costs as their primary financial worry. Modern restaurant inventory management systems are a vital solution that provides immediate tracking – something traditional methods can’t deliver.

Let’s explore why FIFO falls short, discover how restaurant inventory software provides better solutions, and learn applicable ways to enhance your restaurant’s inventory operations. Smart food waste control boosts profits and is vital for sustainability.

The FIFO Method in Restaurant Inventory: What It Is and Why It’s Popular

The FIFO (First-In, First-Out) method stands as one of the oldest ways to manage restaurant inventory. This approach has become deeply rooted in kitchen operations throughout the industry, despite its practical limitations.

How FIFO works in theory

FIFO builds on a simple idea: use the oldest inventory items first. You need to arrange your storage areas—walk-in refrigerators, dry storage, or freezers—to keep older products up front and use them before newer deliveries. The system works when staff date all incoming items and put them behind the existing stock of the same product. This rotation system will give a way to use everything before it expires, which cuts waste and keeps food quality consistent.

Why do restaurants adopt FIFO?

Restaurants choose FIFO because it matches simple accounting principles. Using older ingredients first makes sense to prevent spoilage. Restaurant owners often pick this method since it’s been the go-to recommendation for decades. The system looks straightforward on paper—you don’t need fancy restaurant inventory software or complex training programs to get started.

Common assumptions behind FIFO

FIFO’s popularity stems from several assumptions that don’t always match the reality of busy kitchens. Restaurant managers expect their staff to check dates and rotate stock properly, even during rush hours. They also assume storage areas stay perfectly organised, where everyone can see all products and their purchase dates clearly. The biggest problem? FIFO assumes steady product usage patterns, but real-life kitchens face unpredictable swings in demand.

FIFO’s straightforward nature explains why it’s so popular in restaurant inventory management systems. Yet it’s just one piece of the inventory management puzzle. The next sections will take a closer look at more advanced methods like live tracking through specialised restaurant inventory management system solutions that often work better, especially for operations with varied inventory needs.

Where FIFO Falls Short in Real-World Restaurant Operations

FIFO looks simple on paper, but restaurants struggle to make it work in their busy kitchens. Let’s get into why this traditional approach often falls short in real life.Mismatch between theory and kitchen reality

FIFO should create a smooth flow of inventory. The reality in busy kitchens paints a different picture. Kitchen staff face huge challenges with limited storage space. Walk-in refrigerators get packed quickly, making perfect stock rotation next to impossible. Weekly deliveries add to the chaos and create mix-ups when systems aren’t rock-solid.

Problems with perishable goods and spoilage

Restaurants using FIFO still waste substantial amounts of food, despite its benefits for perishable items. Older products often get buried behind new deliveries when date labels and storage aren’t organised properly. The system can break down when storage layouts make older stock hard to reach. This creates a trap where older items stay hidden behind newer ones.

Inconsistent staff training and execution

Staff training poses a big challenge, too. Kitchen workers who know different inventory methods find it hard to switch to FIFO. During rush hours, speed becomes more important than proper stock rotation. Staff grabs the most available items instead of checking dates. The whole system can fall apart when just one team member doesn’t follow the rules.Impact on cost of goods sold (COGS)

These FIFO failures hit the bottom line hard. Restaurants waste 4-10% of their purchases, which takes a big toll on COGS—maybe the most crucial financial number for any restaurant. A tiny 1% reduction in waste can boost profit margins substantially. FIFO also creates a gap between costs and revenue because older costs get matched with current revenues.

Better Inventory Strategies Beyond FIFO

Restaurants need better ways to cut waste and boost profits than just sticking to traditional methods. Here are four powerful alternatives that work better than regular FIFO approaches.

Using FEFO (First Expired, First Out)

FEFO looks at expiration dates instead of when items arrive, which works great with food that spoils quickly. This system acts like a smart sorting method that spots which products need to be used right away. The results speak for themselves:- Less wasted product

- Better food safety through steady monitoring

- Happier customers who get fresher products

Setting accurate par levels

Par levels tell you the minimum stock you need between deliveries. You can figure these out by looking at how much you use, when deliveries come, and adding a small safety buffer—usually 10% more than what you use in a week.

The math is simple: Standard Inventory Depletion + Safety Net = Par Level

Let’s say you go through 20 bags of French fries weekly. Add a 10% safety margin, and your par level becomes 22 bags. This way, you’ll never run out between deliveries.

Cycle counting and real-time tracking

Cycle counting beats full inventory counts by focusing on small sections of inventory throughout the year. This approach helps you fill orders faster, serve customers better, and know exactly what you have in stock.

Your most expensive or quick-selling items need more frequent counts—maybe daily or weekly. Slower-moving items can be checked monthly. The key is consistency in your counting schedule.

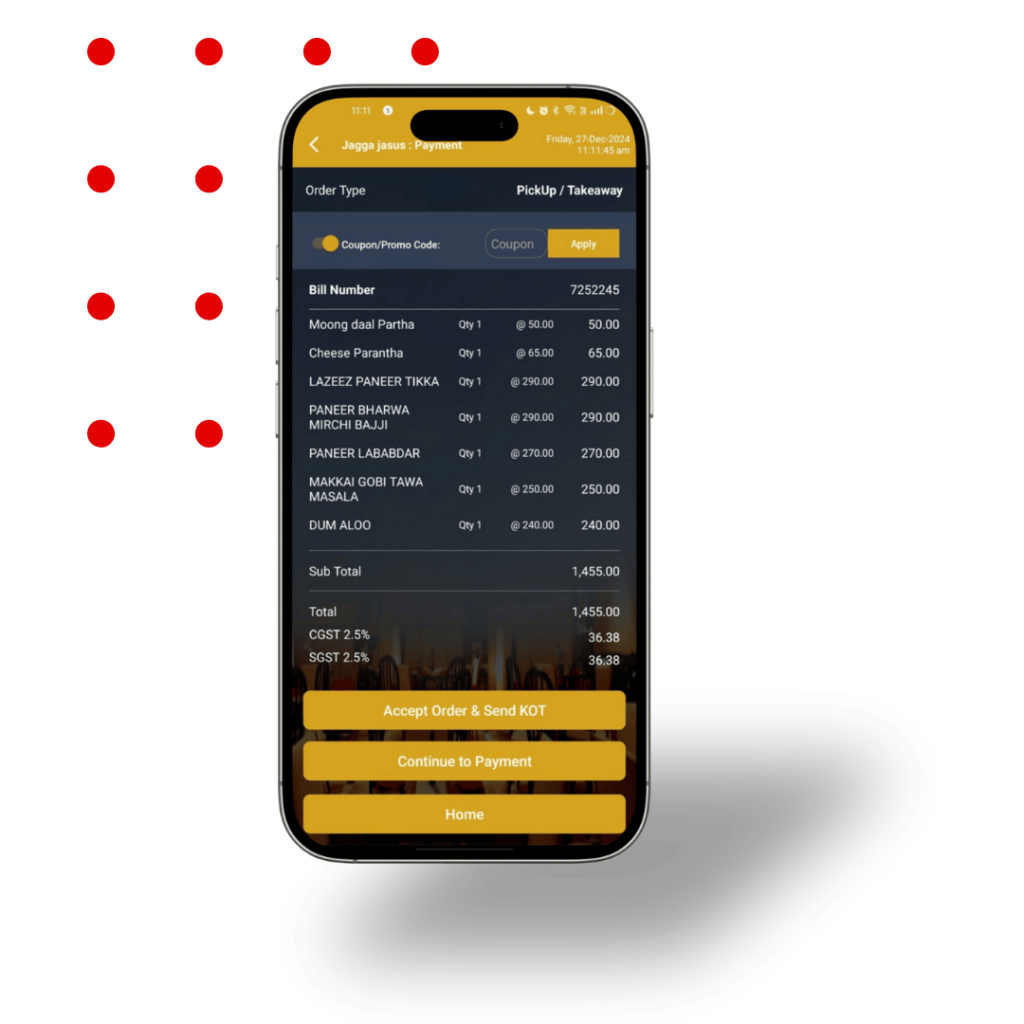

Utilising restaurant inventory software

Modern inventory systems have changed how restaurants track their stock. These systems work directly with your POS, and your inventory updates automatically when orders come in. Good inventory software gives you clear advantages:- No more manual counting errors

- Live data shows what you’ll need

- Recipe tools help maximise profits

- Waste tracking helps cut losses

How to Fix Your Restaurant Inventory Management System

Your restaurant’s inventory challenges need systematic changes. These five strategies will boost your bottom line right away.Train staff on inventory best practices

Staff training investment matters. Well-trained employees reduce errors, streamline processes, and own the inventory processes. Standardised procedures help in receiving, storing, and tracking inventory. Job-specific training boosts staff confidence and efficiency.Use restaurant inventory management systems with automation

Restaurant inventory management software cuts manual errors and saves over 40 staff hours each month. These systems update stock levels automatically with new orders. They predict demand using past data and alert staff when inventory hits par levels.

Track waste and shrinkage regularly

Waste monitoring reveals loss patterns. A waste log should record time, date, item, amount, and waste reasons. Statistics show that 47% of restaurants track waste. This practice uncovers ways to improve margins.Integrate POS with inventory tools

Your point-of-sale system’s connection with inventory management gives up-to-the-minute data about stock levels. This setup automatically reduces inventory after each sale and helps predict needs better.Monitor KPIs like inventory turnover and food cost percentage

Important performance indicators include:

- Inventory turnover ratio = COGS ÷ Average Inventory

- Food cost percentage = Food cost ÷ Total sales × 100

These numbers show ways to cut waste and boost profits.

Conclusion

Modern restaurant kitchens need more than just FIFO to manage their inventory well. While FIFO looks good in theory, it doesn’t work well in busy restaurants with cramped storage and varying staff routines. This leads restaurants to waste much of their food purchases, which cuts into their profits.

You’ll find better options than FIFO out there. FEFO (First Expired, First Out) works better for perishable items because it focuses on actual expiration dates instead of arrival times. Setting the right par levels helps maintain ideal stock between deliveries. Cycle counting and live tracking through specialised software give you much better control than old methods would.

Your inventory system needs well-trained staff to work. The best systems will fail without employees who know and follow the right steps. Waste tracking helps spot patterns you might miss, and POS integration cuts down on the mistakes that come with manual inventory management.

Better inventory management makes a huge difference to your finances. Small cuts in food waste can boost your bottom line, since food makes up about a third of restaurant costs. Moving away from familiar systems like FIFO might seem tough at first, but the rewards are worth it.

The best restaurant inventory management needs the right systems, trained people, and regular monitoring. Whether you pick FEFO, start cycle counting, or use complete inventory software, moving past FIFO is vital for better profits and green practices. Your restaurant can do better than old inventory methods that waste food and money. Now is the time to update your approach.